Making processes and tasks more efficient – Robotic Process Automation (RPA) offers a solution for precisely this. But what exactly is RPA and what can it do? In our blog series, we examine the technology from various angles, addressing both social and technical issues as well as the dos and don’ts of RPA.

In the first part, we will first take a look at how RPA fits into the context of the Industrial Revolution. We will also use a typical application process – as found in a wide variety of areas – to show how automation can make the process more time-efficient.

The Fourth Industrial Revolution – an overview

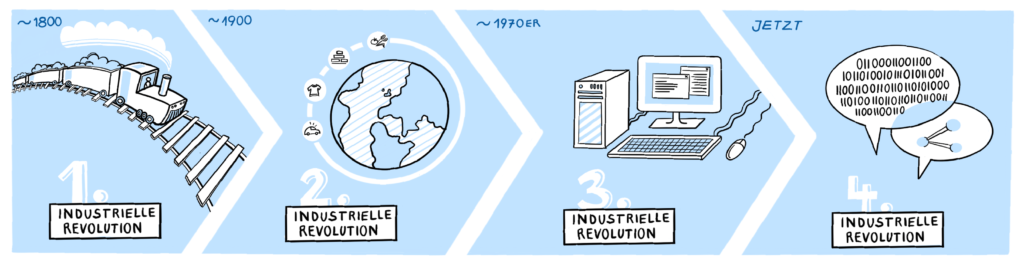

The Industrial Revolution developed ways to reduce manual labour and make it more efficient with the help of machines. It began with the invention of the steam engine at the end of the 18th century, followed by the advent of electricity and petroleum, as well as mass production and assembly line manufacturing at the end of the 19th century. With the development of semiconductors, the creation of computers and the internet, the 20th and 21st centuries saw the emergence of finally, the so-called information society.

In 2011, the term ‘Fourth Industrial Revolution’ was coined by economist Klaus Schwab (founder of the World Economic Forum) at the Hannover Messe trade fair. The term is characterised by the development of the Internet of Things (IoT), robotics and artificial intelligence. Digitalisation and automation play a central role in all organisations, as agile and collaborative companies understand this to be an important prerequisite for the rapid delivery of products and services.

The Fourth Industrial Revolution is not defined by a series of new technologies per se, but by the transition to new systems that build on the infrastructure of the digital revolution.

Klaus Schwab, “Die Vierte Industrielle Revolution”

The basic principle therefore consists of combining physical machines with digital processes that can serve as decision-making aids.

The advantages of the Fourth Industrial Revolution include intelligent decision-making, which contributes to increased productivity, competitiveness and workplace safety, as well as the vast amount of data that is processed every day.

To bring about change at the corporate level, cross-functional thinking that encompasses all areas is required. Nowadays, different disciplines and departments are working together in an increasingly integrated manner. Ultimately, these must be harmonised, otherwise processes can no longer be completed in their entirety due to misunderstandings between the people or IT systems involved. Unfortunately, it is undisputed that complexity is increasing rather than decreasing.

What is misleading in connection with RPA is the sometimes one-sided consideration of certain information. For example, the World Economic Forum (WEF) report ‘The Future of Jobs Report 2020’ predicts that by 2025, approximately 85 million jobs could be displaced by technology. However, it must also be taken into account that approximately 97 million new roles and jobs will be created that are adapted to the division of tasks between humans and robots (source: World Economic Forum, The Future of Jobs Report 2020).

This change requires new ideas, strategies and ways of thinking. Germany was the first country to put the future-oriented Industry 4.0 project on the government agenda as part of its high-tech strategy. Since 2013, work has been underway to develop solutions to ‘tap into optimisation potential in production and logistics’ and ‘make work processes flexible and adaptable for both employees and companies’ (source: BMBF, Industry 4.0).

Automation on the rise

With the advancement of the fourth industrial revolution, artificial intelligence and automation are being used more and more frequently. The transition from manual to automated processes makes it possible to improve the quality of the products and services offered, eliminate errors and increase the speed of processes and workflows. Through this integrative task, RPA is a very good tool for realising the possibilities of the fourth industrial revolution.

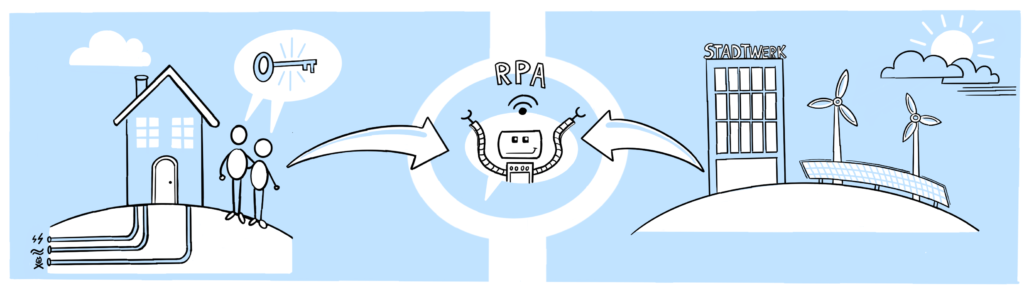

Robotic process automation is a software tool that mimics human behaviour and the interaction between different systems, often eliminating manual, repetitive and monotonous processes that have to be carried out by employees.

Making processes more time-efficient – an example

Even before the fourth industrial revolution, we have been familiar with submitting applications on the one hand and processing them on the other. This applies to both our personal and professional lives. A clear example for a home builder is applying for a new water, electricity, gas or district heating connection. Here, a customer (applicant) fills out an application form manually. This is then read by the relevant department and the information is transferred field by field into the company’s own ERP system. The information is then managed there, but in very few cases is it used for further processes within the company.

Automation reduces the time required to process applications to just four minutes – from the moment the application is submitted to the first result in the form of a quote for the construction of a new standard house connection. This allows employees to focus on more demanding tasks that cannot be performed by a machine.

Simple and quick entries and the resulting prompt response therefore benefit both employees and customers.

In general, at least 35% of the time required for a task can be saved through automation.

The most important points summarised:

- The fourth industrial revolution involves combining physical machines with digital processes.

- Repetitive tasks have always been the subject of automation.

- The transition from manual to automated processes makes it possible to improve the quality of the products and services offered, eliminate errors and increase the speed of processes and workflows.

- Robotic Process Automation (RPA) is a software tool that helps to make this transition a success.

- Automation can significantly reduce the time required for tasks.

Outlook

In our next blog post, we will take a closer look at the term RPA and show how automation can make everyday work easier in concrete terms.